GW unobstructed pipeline sewage pumpEasy to install, versatile for general usePipeline pumpIt is used for pressurized water supply in high-rise buildings and can also transport wastewater containing granular fibers. In addition to transporting wastewater, it is also suitable for use as a drainage pump, filtration flushing condensation circulation pump, etc. This series of pumps adopts a unique impeller structure and a new type of mechanical seal, which can effectively transport solids and long fibers. Compared with traditional impellers, the impeller of this pump adopts a single channel or double channel form, which is similar to a curved pipe with the same cross-sectional size and has very good flow characteristics. Coupled with a reasonable volute chamber, the pump has high efficiency and the impeller has undergone dynamic and static balance tests, making the pump operate without vibration.

GW unobstructed pipeline sewage pumpWhat are the advantages?

1. The GW pipeline sewage pump is directly connected to the motor and coaxial, belonging to the electromechanical integration product, with a compact structure and stable performance.2. The design of anti clogging hydraulic components for large flow channels greatly improves the ability of pollutants to pass through, effectively passing through 5 times the fiber material of the pump diameter and solid particles with a diameter of about 50% of the pump diameter.

3. Reasonable design, reasonable matching motor, high efficiency, low noise, and significant energy-saving effect.

4. The mechanical seal adopts hard and wear-resistant tungsten carbide, which has the characteristics of durability and wear resistance, and can ensure the safe and continuous operation of the pump for more than 8000 hours.

5. The pump is a vertical structure, with the inlet and outlet centerlines on the same horizontal line, and the inlet and outlet flange specifications are the same, making installation and disassembly very convenient.

6. Small footprint, no need to build a computer room, can save a lot of infrastructure costs; By adding protective covers to the fan blades of the motor, the entire machine can be operated outdoors.

GW unobstructed pipeline sewage pumpEnvironmental requirements for use

The operating environment temperature of GW type pipeline sewage pump is ≤ 40 ℃, and the humidity is ≤ 95%; Altitude ≤ 1000 meters.The medium temperature shall not exceed 60 ℃, and the medium density shall be 1-1.3kg/dm3.

The range of use for cast iron material is from pH 5 to 9.

Stainless steel material can be used with general corrosive media.

The altitude of the usage environment should not exceed 1000 meters. If it exceeds the above conditions, it should be mentioned when placing an order to provide you with more reliable products.

Note: If the user has special requirements for temperature, medium, etc., please specify the detailed information of the conveying medium when ordering, so that our unit can provide more reliable products.

GW unobstructed pipeline sewage pumpMain application areas

1. The GW type pipeline sewage pump is used for the discharge of severely polluted wastewater from factories and commercial units.2. Urban sewage treatment plant discharge system.

3. Sewage drainage system in residential areas.

4. Wastewater discharge from hospitals, hotels, and high-rise buildings.

5. Subway, basement, civil air defense system drainage station.

6. Discharge of slurry in municipal engineering and construction sites.

7. The water supply system of water companies and factories.

8. Wastewater discharge from breeding farms or rural biogas digesters, irrigation of farmland.

9. Exploration of mines and supporting equipment for water treatment.

10. Suitable for water supply and drainage in hydraulic engineering.

GW unobstructed pipeline sewage pumpModel representation method

GW unobstructed pipeline sewage pumpSelection parameters

|

model |

internet traffic |

lift |

rotational speed |

power |

|

50GW20-7-0.75 pipeline sewage pump |

20 |

7 |

2900 |

0.75 |

|

50GW10-10-0.75 pipeline sewage pump |

10 |

10 |

2900 |

0.75 |

|

50GW10-12-1.1 pipeline sewage pump |

10 |

12 |

2900 |

1.1 |

|

50GW25-10-1.5 pipeline sewage pump |

25 |

10 |

2900 |

1.5 |

|

50GW20-15-1.5 pipeline sewage pump |

20 |

15 |

2900 |

1.5 |

|

50GW15-15-1.5 pipeline sewage pump |

15 |

15 |

2900 |

1.5 |

|

50GW15-20-2.2 pipeline sewage pump |

15 |

20 |

2900 |

2.2 |

|

50GW15-18-2.2 pipeline sewage pump |

15 |

18 |

2900 |

2.2 |

|

50GW15-25-2.2 pipeline sewage pump |

15 |

25 |

2900 |

2.2 |

|

50GW27-15-2.2 pipeline sewage pump |

27 |

15 |

2900 |

2.2 |

|

50GW30-14-2.2 Pipeline sewage pump |

30 |

14 |

2900 |

2.2 |

|

50GW42-9-2.2 Pipeline sewage pump |

42 |

9 |

2900 |

2.2 |

|

50GW30-10-2.2 pipeline sewage pump |

30 |

10 |

2900 |

2.2 |

|

50GW20-22-3 pipeline sewage pump |

20 |

22 |

2900 |

3 |

|

50GW25-18-3 pipeline sewage pump |

25 |

18 |

2900 |

3 |

|

50GW15-30-3 pipeline sewage pump |

15 |

30 |

2900 |

3 |

|

50GW25-20-4 pipeline sewage pump |

25 |

20 |

2900 |

4 |

|

50GW40-15-4 pipeline sewage pump |

40 |

15 |

2900 |

4 |

|

50GW20-30-5.5 pipeline sewage pump |

20 |

30 |

2900 |

5.5 |

|

50GW20-40-7.5 pipeline sewage pump |

20 |

40 |

2900 |

7.5 |

|

50GW25-35-7.5 pipeline sewage pump |

25 |

35 |

2900 |

7.5 |

|

50GW30-40-7.5 pipeline sewage pump |

30 |

40 |

2900 |

7.5 |

|

65GW25-10-1.5 pipeline sewage pump |

25 |

10 |

2900 |

1.5 |

|

65GW35-7-2.2 Pipeline sewage pump |

35 |

7 |

2900 |

2.2 |

|

65GW30-10-2.2 Pipeline sewage pump |

30 |

10 |

290 |

2.2 |

|

65GW25-15-2.2 Pipeline sewage pump |

25 |

15 |

2900 |

2.2 |

|

65GW37-13-3 pipeline sewage pump |

37 |

13 |

2900 |

3 |

|

65GW30-22-4 pipeline sewage pump |

30 |

22 |

2900 |

4 |

|

65GW40-15-4 pipeline sewage pump |

40 |

15 |

2900 |

4 |

|

65GW25-30-5.5 pipeline sewage pump |

25 |

30 |

2900 |

5.5 |

|

65GW32-25-5.5 pipeline sewage pump |

32 |

25 |

2900 |

5.5 |

|

65GW40-30-7.5 pipeline sewage pump |

40 |

30 |

2900 |

7.5 |

|

65GW30-40-7.5 pipeline sewage pump |

30 |

40 |

2900 |

7.5 |

|

65GW30-45-11 pipeline sewage pump |

30 |

45 |

2900 |

11 |

|

65GW35-50-15 pipeline sewage pump |

35 |

50 |

2900 |

15 |

|

65GW35-60-18.5 pipeline sewage pump |

35 |

60 |

2900 |

18.5 |

|

80GW40-7-2.2 pipeline sewage pump |

40 |

7 |

2900/1450 |

2.2 |

|

80GW43-13-3 pipeline sewage pump |

43 |

13 |

2900 |

3 |

|

80GW40-15-4 pipeline sewage pump |

40 |

15 |

2900 |

4 |

|

80GW50-20-5.5 pipeline sewage pump |

50 |

20 |

2900 |

5.5 |

|

80GW40-25-5.5 pipeline sewage pump |

40 |

25 |

2900 |

5.5 |

|

80GW30-30-5.5 pipeline sewage pump |

30 |

30 |

2900 |

5.5 |

|

80GW65-25-7.5 pipeline sewage pump |

65 |

25 |

2900 |

7.5 |

|

80GW50-20-7.5 pipeline sewage pump |

50 |

20 |

2900 |

7.5 |

|

80GW30-40-7.5 pipeline sewage pump |

30 |

40 |

2900 |

7.5 |

|

100GW85-10-4 pipeline sewage pump |

85 |

10 |

1450/2900 |

4 |

|

100GW50-20-5 pipeline sewage pump |

50 |

20 |

1450/2900 |

5.5 |

|

100GW65-15-5.5 pipeline sewage pump |

65 |

15 |

1450/2900 |

5.5 |

|

100GW100-10-7.5 pipeline sewage pump |

100 |

10 |

1450/2900 |

7.5 |

|

100GW85-15-7.5 pipeline sewage pump |

85 |

15 |

1450/2900 |

7.5 |

|

100GW80-20-7.5 pipeline sewage pump |

80 |

20 |

1450/2900 |

7.5 |

|

100GW100-15-7.5 pipeline sewage pump |

100 |

15 |

1450/2900 |

7.5 |

|

100GW100-25-11 pipeline sewage pump |

100 |

25 |

1450/2900 |

11 |

|

100GW100-30-15 pipeline sewage pump |

100 |

30 |

1450/2900 |

15 |

|

100GW100-35-18.5 pipeline sewage pump |

100 |

35 |

1450/2900 |

18.5 |

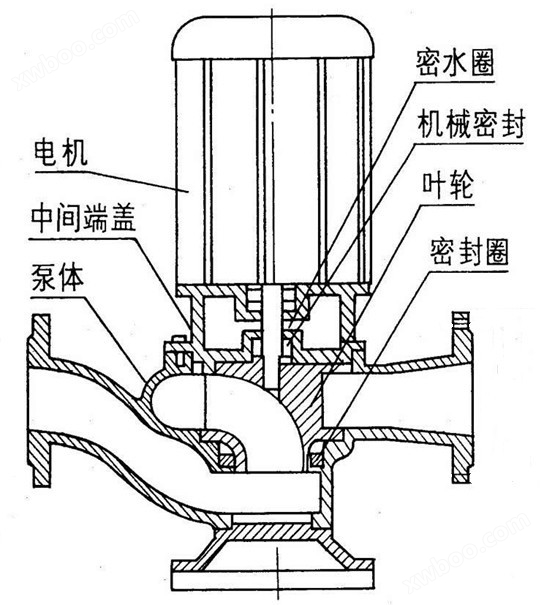

GW unobstructed pipeline sewage pumpStructural diagram

GW unobstructed pipeline sewage pumpInstallation and usage requirements

Firstly, check if the external fasteners have become loose during transportation.2. Check if the power supply voltage meets the requirements of the motor nameplate.

3. Connect the power and try to turn it on to see if the impeller rotates in the direction indicated on the pump. If the direction is reversed, simply swap any two-phase wires in the cable. During the test run, the time should not be too long to avoid burning out the seal.

4. Install the pump and start it up for operation. It is best to install the pump foot screws.

Inspection and maintenance of GW type pipeline sewage pump

Before using the GW type pipeline sewage pump, the insulation resistance of the motor winding to the casing should be checked. If it is lower than 0.5 megaohms, the stator must be dried and the insulation resistance must be increased before use.

If the gap between the impeller and the oil seal at the inlet of the pump body exceeds 2mm, the wear-resistant oil seal should be replaced.

When there is water leakage in the pump seal, the seal should be replaced in a timely manner. When replacing, the static seal should be installed flat and solid first, and then the dynamic seal should be sealed on the shaft.

4. When replacing the impeller, use a puller to pull it out, and do not use a hammer to strike forcefully to avoid damaging the shaft alignment.

Common causes of faults in GW type pipeline sewage pumps

1. No water output, heavy and high particle size of the liquid being pumped; Blockage of liquid flow channel; Wrong impeller direction; The rod material is sucked into the impeller and gets stuck; The height of the pipeline outlet exceeds the rated head height.

2. Insufficient flow and low head. Low voltage, wrong impeller direction, or worn wear-resistant seal; The heavy particle size of the liquid is too high.

3. Low insulation resistance, humid surrounding environment, and severe mechanical seal leakage.

Please provide as much as possible for ordering:1. Model 2. Diameter 3. Head (m) 4. Flow rate 5. Motor power (KW) 6. Speed (R/min) 7. Material with accessories 8. Voltage (V)

Welcome to visit our Quanda Pump Valve【www.quandabf.cn】If you have any questions You can call us and we will do our best to provide you with high-quality service.